Innovations

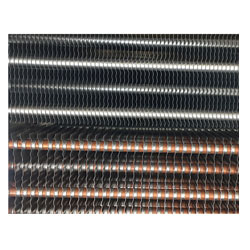

At Danvita we are committed to a practice of consistently innovating in order to provide heat exchange solutions to our industry as a whole. We have the capability in design engineering fin pattern, Quantum™ fin design, wide fin patterns and geometrics, coil coating, 5mm micro tube coils and new technology.

Aluminium Coils

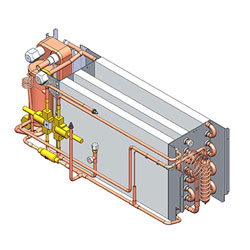

Our Aluminium coils are best suitable for evaporator, condenser, combi (heater and evaporator) coils.

These coils provide similar capacity as Copper coils due to the QUANTUM ™fin design and Rifled or Inner grooved tubes.

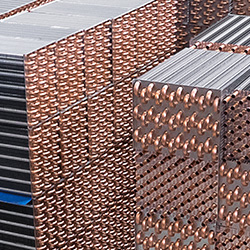

LIGHTER IN WEIGHT: Aluminium coils are 1/3rd weight of a Copper coil, thus easier to handle during assembly and installation and reduce equipment weight.

CHEAPER & STEADY PRICE: Aluminium metal price is 1/3rd of Copper price thus offers price reduction and stability

DROP IN REPLACEMENT: Same foot print and same end connections as Copper tube coil

EASY IMPLEMENTATION: Faster Development, Cheaper Development Cost and requires No Modification at the Customer End / Equipment

EASY CERITIFICATION: Similar performance, similar UL Design and UL Burst pressures like Copper tube coils

CORROSION RESISTANT: 10% Of Copper Tube Evaporators Leak Due to Formicary Corrosion. Formicary Corrosion has No Effect on Aluminium Tube Coils Galvanic Corrosion occurring due to dissimilar metals i.e. Copper and Aluminium does not occur in Aluminium Fin and Aluminium Tube Coils

Danvita Aluminium coils are suitable for all major Refrigerants: R-134a, R 404a, R –407C, R – 410a, R290, Iso Butane and other hydrocarbon refrigerants.