Case Studies

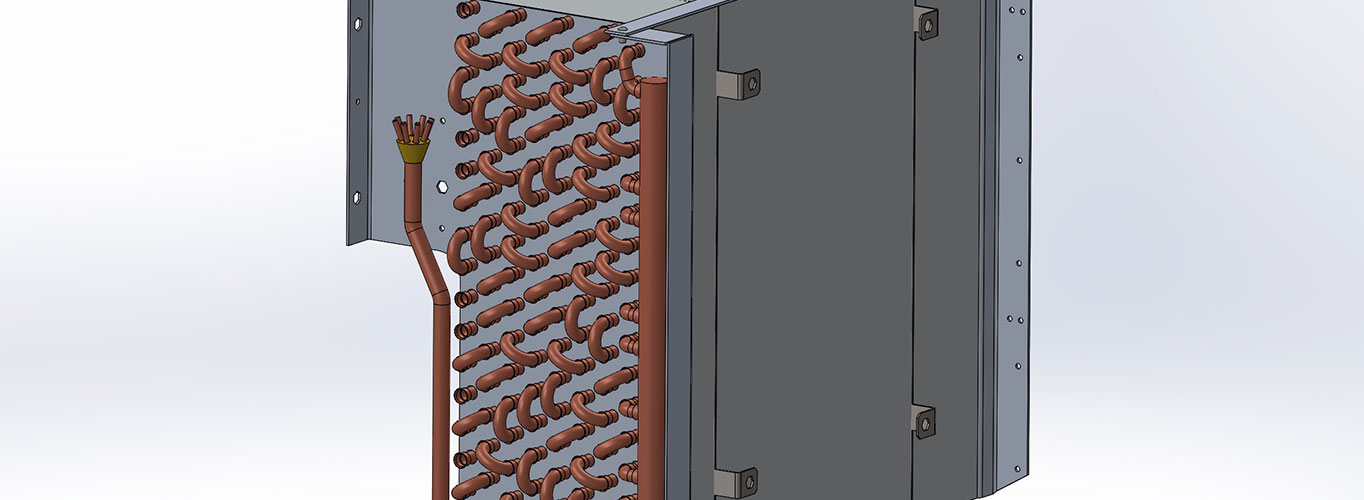

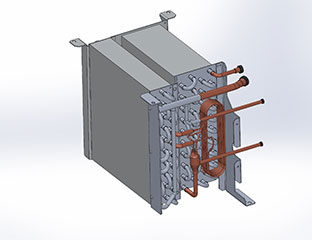

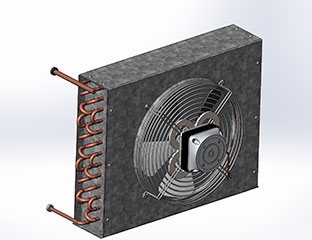

Europe based customer who is into manufacturing Transport HVAC and Refrigeration systems, approached Danvita to develop evaporators for their Truck Refrigeration systems.

Challenge

To design an evaporator with a very high COP and meet the European performance and efficiency standards.

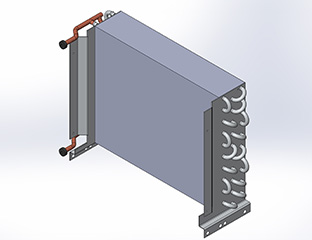

Limited space available as the evaporator is mounted inside the trailer.

Complex Airflow direction over the evaporator.

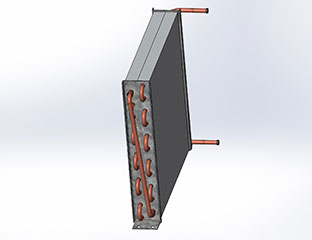

Very Low Refrigerant pressure drop required.

Wider fin spacing or Lower Fins per inch on the coil to avoid frequent defrosting.

Solution

Design engineers at Danvita pooled all its resources, their collective experience, and innovative ideas to arrive at a viable proposal. CFD ( Computational Fluid Dynamics) tool was used to understand the complex airflow pattern over the coil.

Capacity simulation programme was used to calculate the optimum capacity of the evaporator coil and its sizing.

A unique Refrigerant circuiting was designed to keep the Refrigerant pressure drop low as per the requirement.

Conclusion

Danvita’s engineered evaporator coils were field tested and found to provide just about the required capacity, in spite of all the limitations.